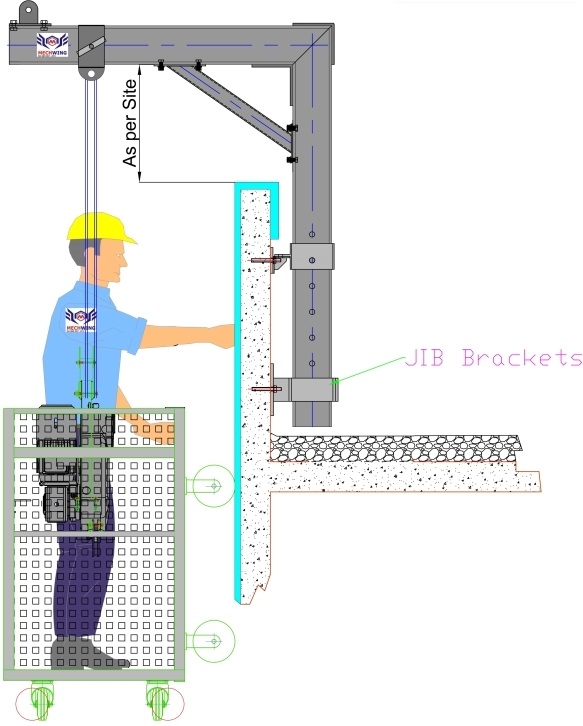

Technical Details

AUTOMATIC REMOTE CONTROL MACHINES (BMU)

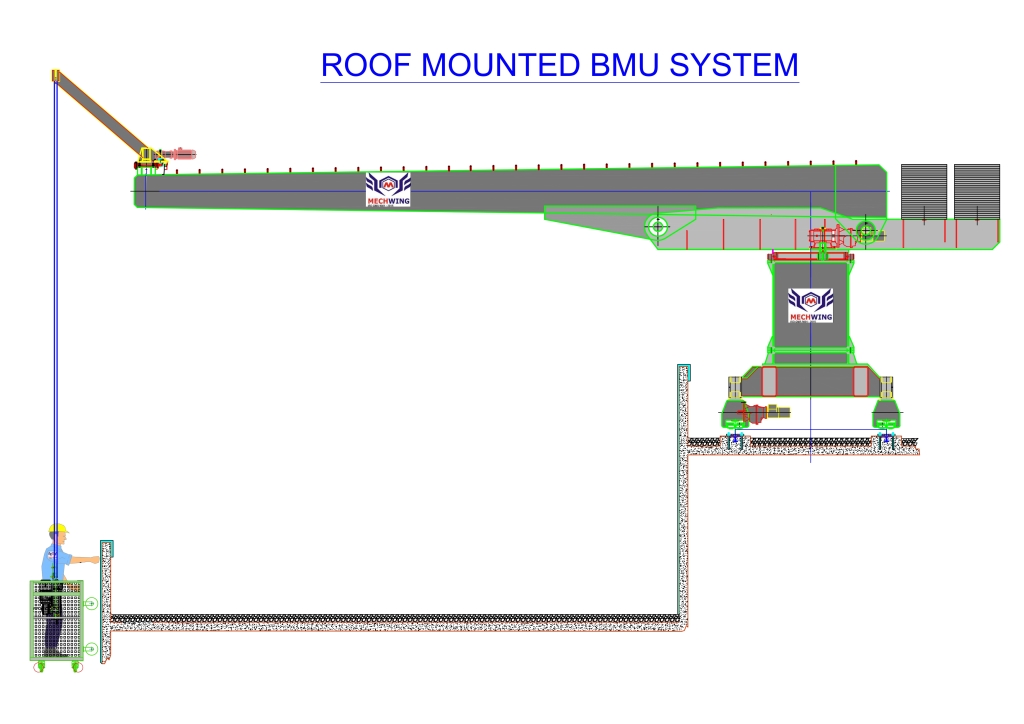

Automatic remote control machine are single jib Building Maintenance Unit (BMU), it is roof mounted machine working either by traversing along the track/ guide or fixed at designated levels, the roof machine will includes M.S structure and frame, the jib, the slewing mechanism, the spreader bar slewing mechanism and the housing with travelling mechanism.

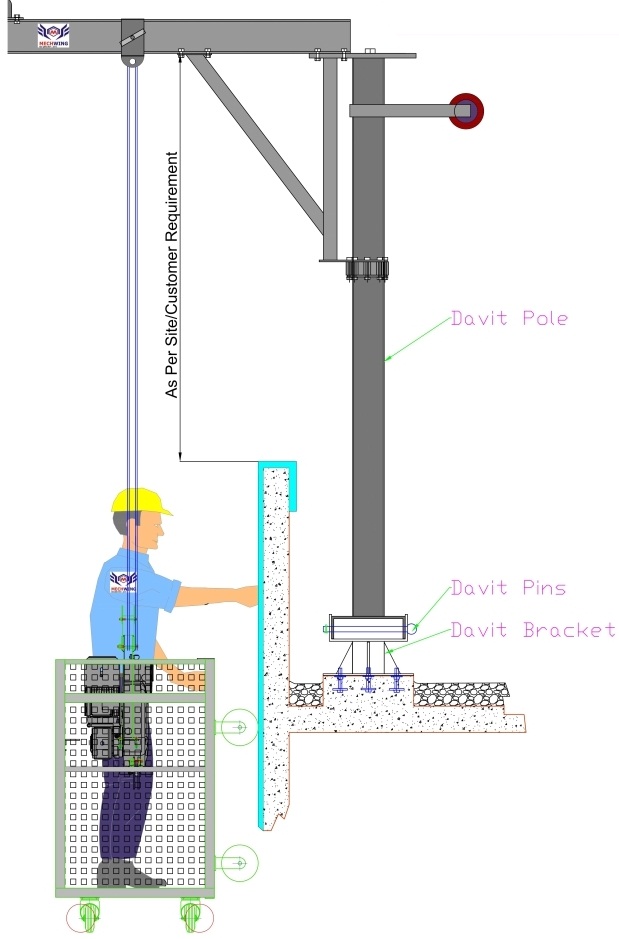

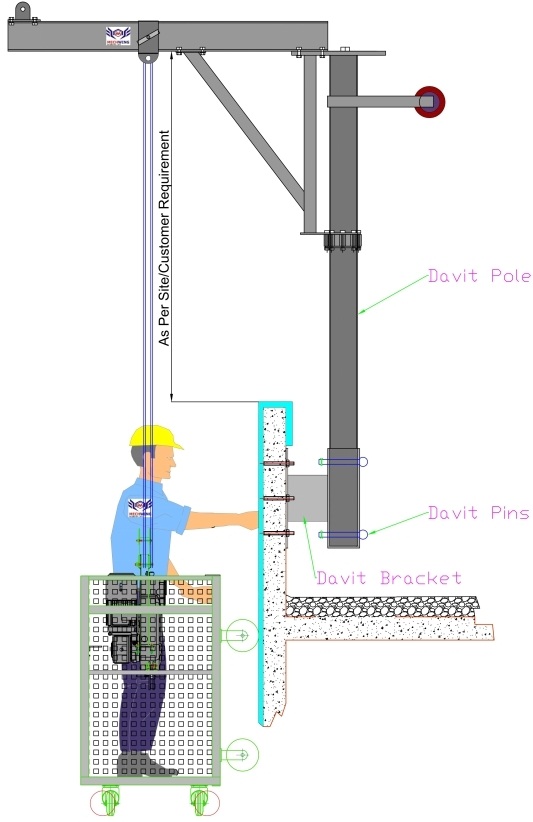

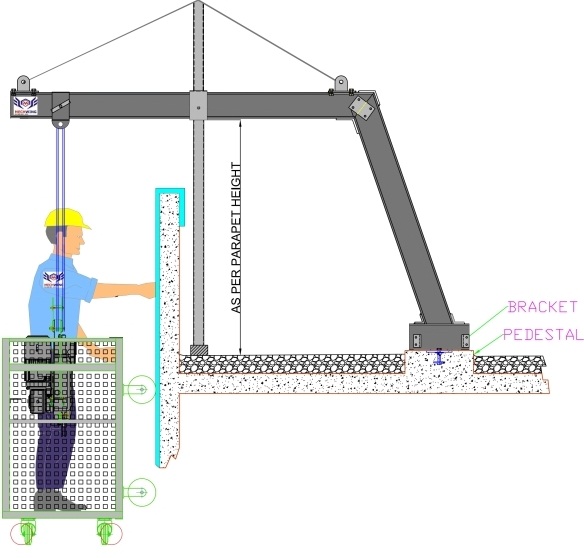

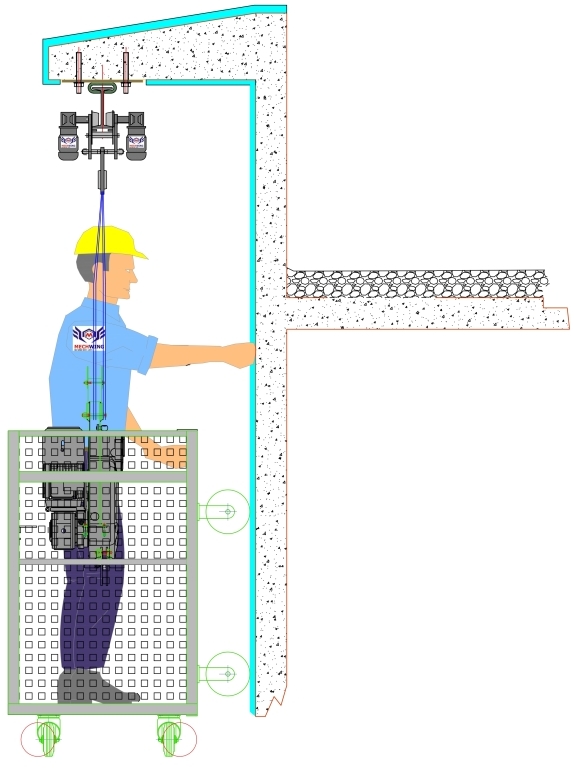

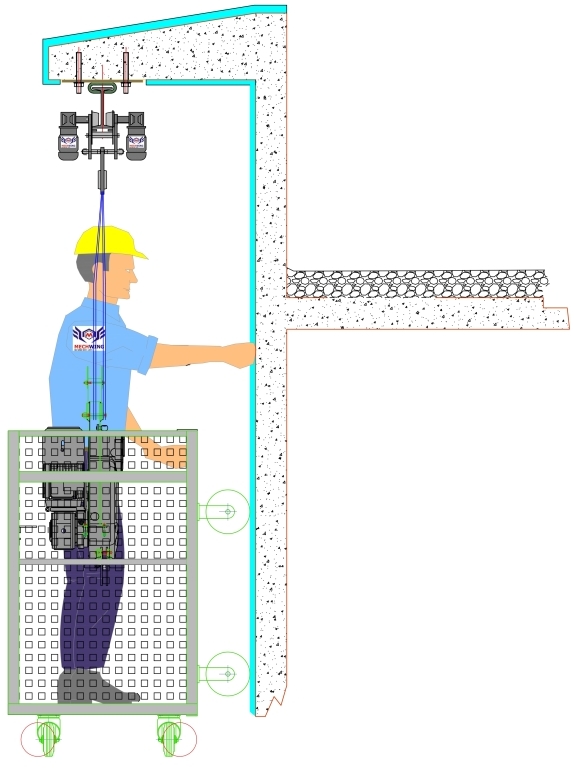

Machine Hoisting :

The hoist is within the working cradle, it is basic system with advantage of using the same cleaning cradle with other system is it machine, monorail or davit by easy switching.

Traversing Option :

Rail Track traversing on galvanized steel double rail track on the roof of the building joined via concrete up stands spaced at intervals, in this we have advantage to depend on the machine loading to keep the counterweight less. Guide rail on concrete runway, the roof machine will travel along the leveled concrete pathway guided by steel angle, the machine is perfectly counter balanced.

Automatic Remote Control Machine (BMU) Function :

1. Spreader bar to keep cradle parallel to façade (motorized/ manual)

2. Motorized machine slewing

3. Complete Control are given in machine and cradle

4. Wireless control system

Standard Dimension :

Application Height : Upto 120 m

Jib Length : 2000 – 8000 mm

Cradle Length : 1.8 – 2.5 m

Track Gauge : 1500 – 2500 mm

Safe Working Load : 240 kg

Safety Option :

1. Emergency Push Button

2. Traversing Limit Switch

3. Slewing Limit Switch

4. Spreader Bar Slewing Limit Switch

5. Hoist Up Limit Switch

6. Safety Harness Hooking Point

7. Electro-magnetic Brake (Primary Brake)

8. Over Speed Emergency Brake (Secondary Brake)

9. Manual Emergency Descent Release Handle

10. End of Rope Limit Switch

11. Buffer Plates